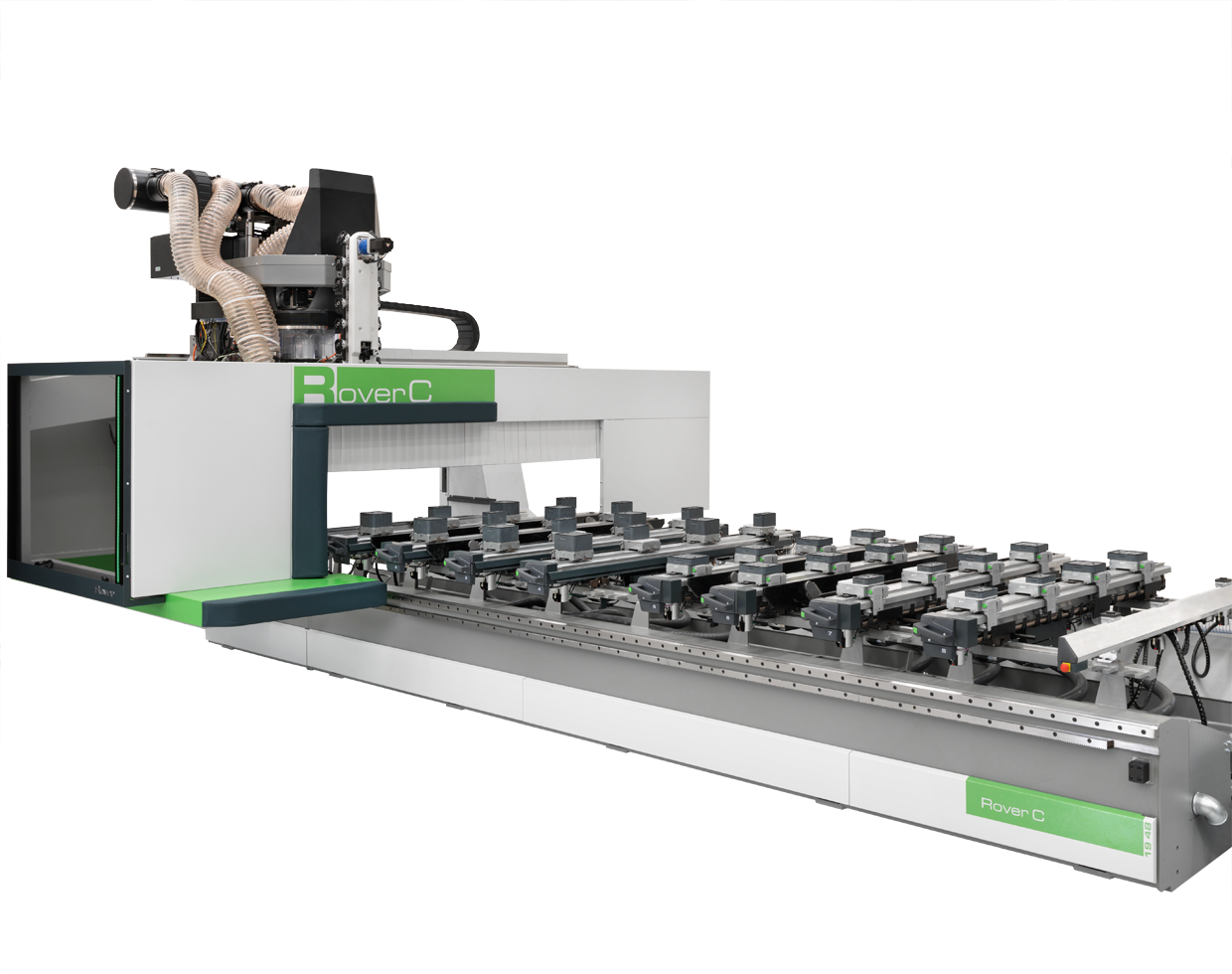

POWER MEETS PRECISION

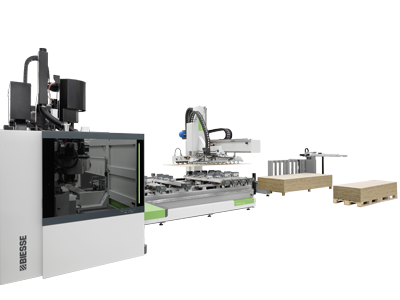

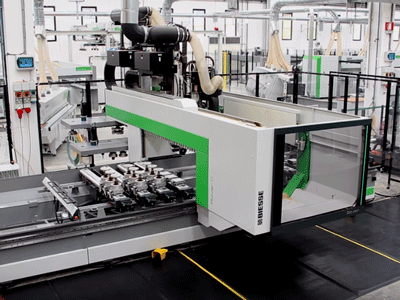

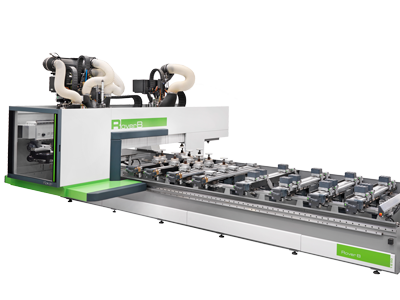

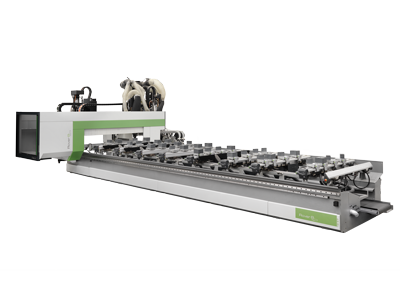

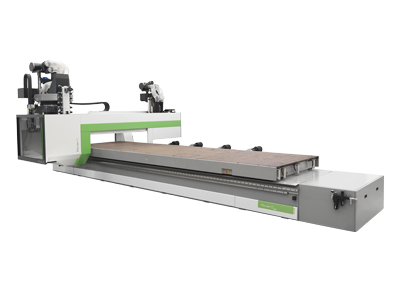

Rover C is the new CNC router processing center for manufacturing furniture, staircase and door and window components of any shape, size and thickness with ease. It was designed to be used for heavy-duty processing that requires large-size tools and aggregates.

TO PRODUCE WITHOUT LIMITS

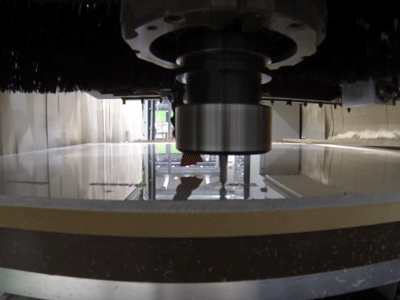

The wood CNC router technology of the new Rover C supports the machining of complex-shaped pieces, guaranteeing quality, precision and absolute reliability over time.

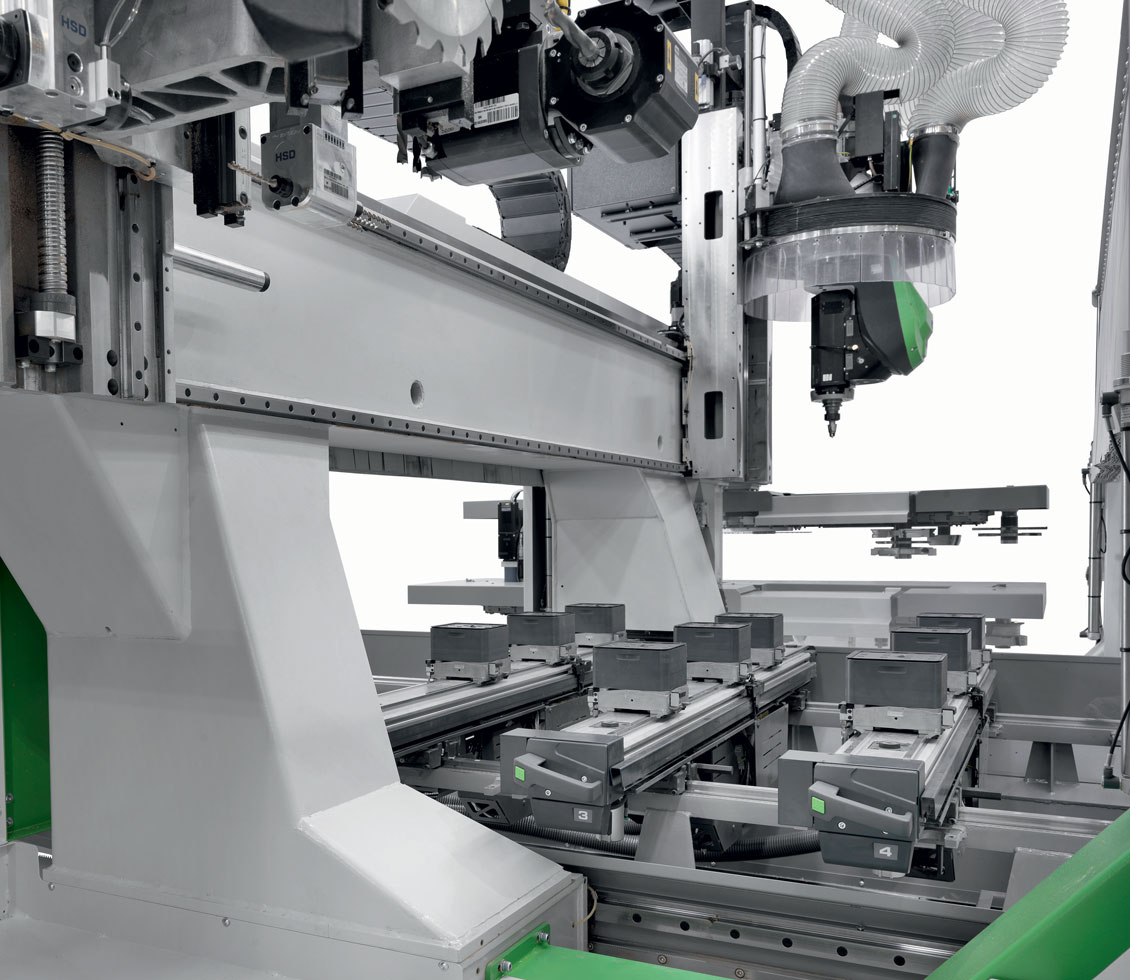

EXTREME POWER

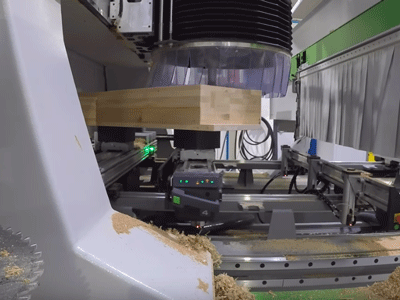

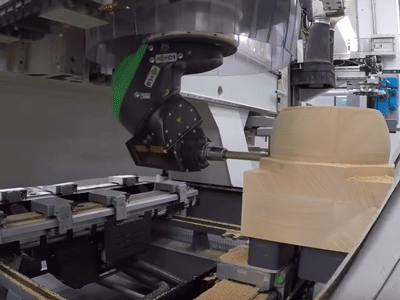

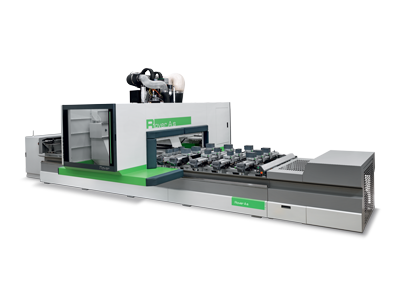

The HSD 5 interpolating axis operating unit with a power of 21.5 kW at 8,000 rpm and 360° continuous rotation on the vertical and horizontal axes, it allows the machining of pieces with complex shapes, guaranteeing quality, precision, and total reliability over time.

Perfect execution of machining operations.

Absolute absence of vibrations thanks to the Gantry structure with double motorization, extremely solid and balanced, designed to raise the standards of precision and reliability in the execution of the work.

PIECE PASSAGE IN Z UP TO 500 MM

Possibility to work even large thicknesses

The extreme stiffness of the structure allows for the processing

on pieces with X / Y / Z dimensions up to 1950x8125x500 mm, and up

to 2250x8125x500 mm as an option, with maximum precision

and finish quality.

ROS

Integrated robot solutions

Biesse offers its customers pragmatic solutions for factory automation.

ROS robotized solutions ensure a marked increase in production and total reliability of both the production process and the unloading operations, even in a wider context of industrial automation.

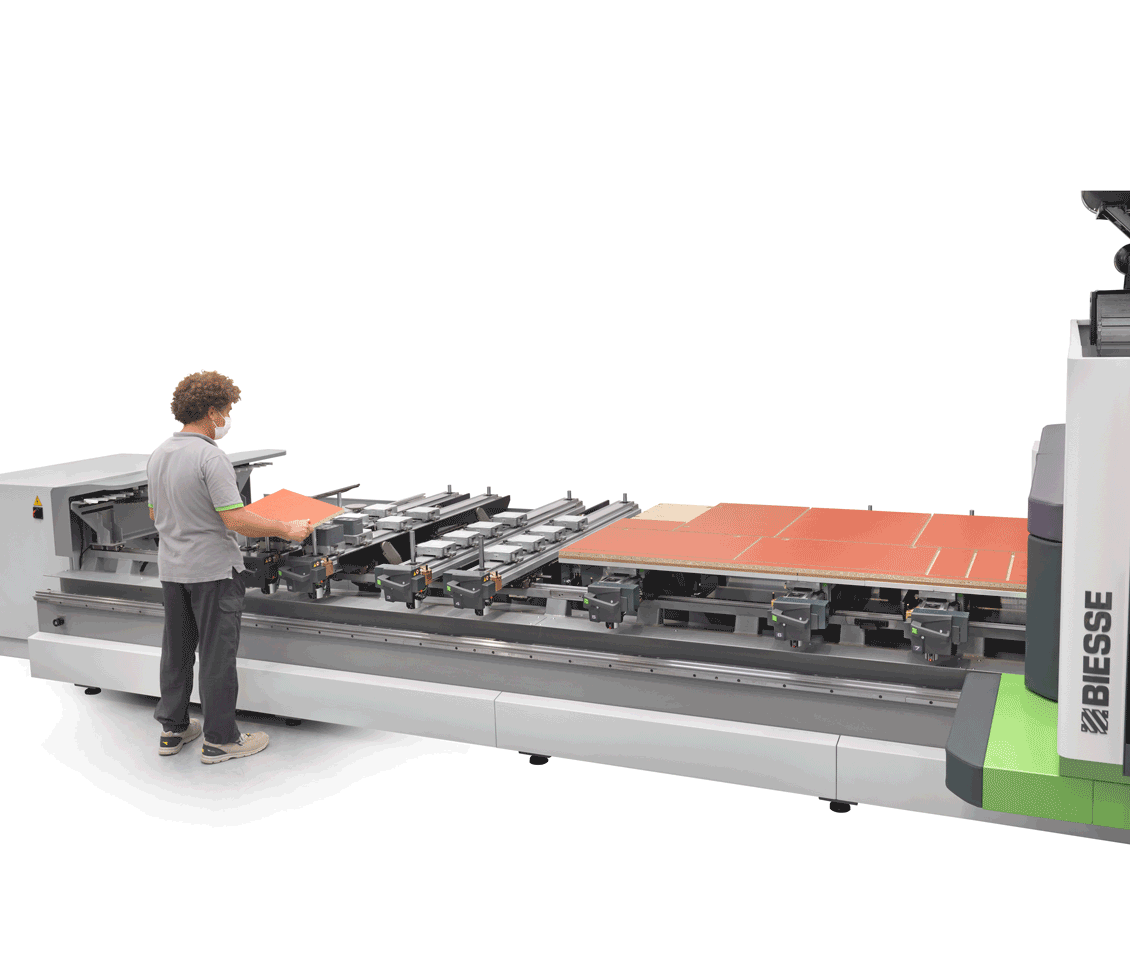

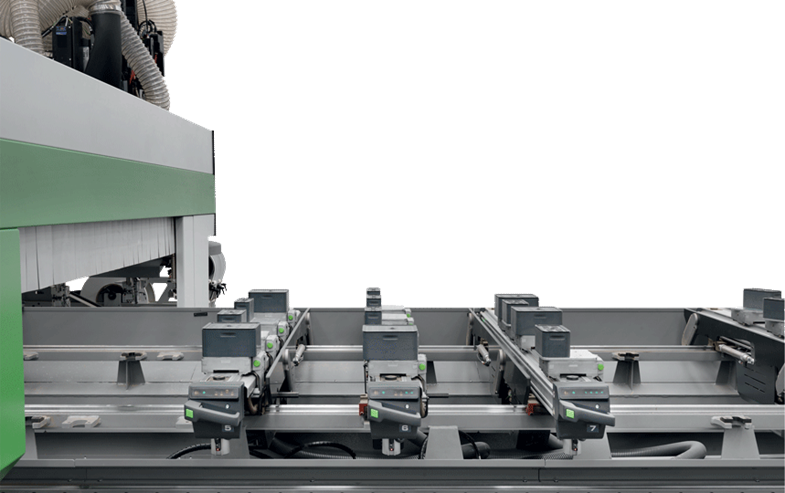

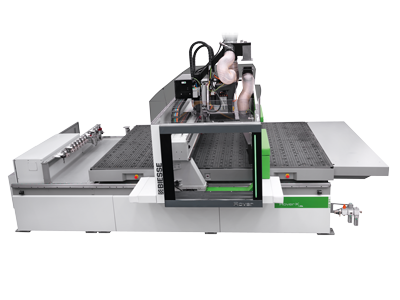

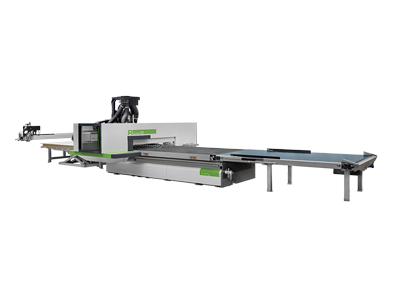

CFT: Two machines in one, guaranteed competitiveness

Rover C with bar table, convertible into a machine with continuous table, allows you to tackle

also nesting, folding

and thin panels.

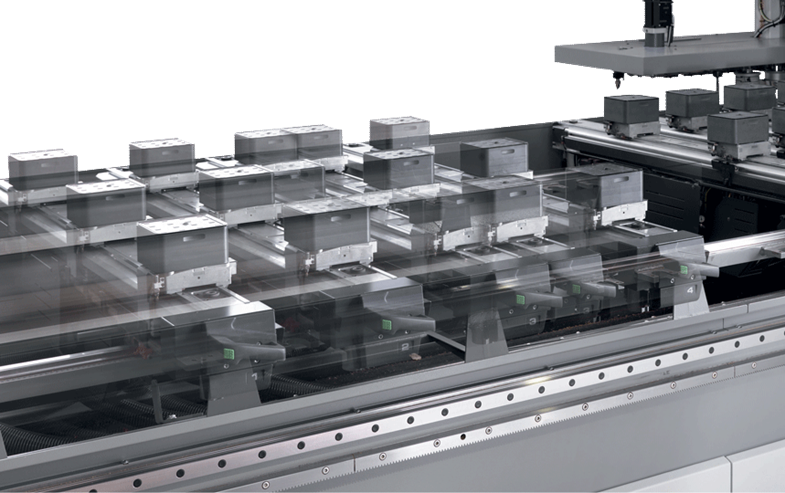

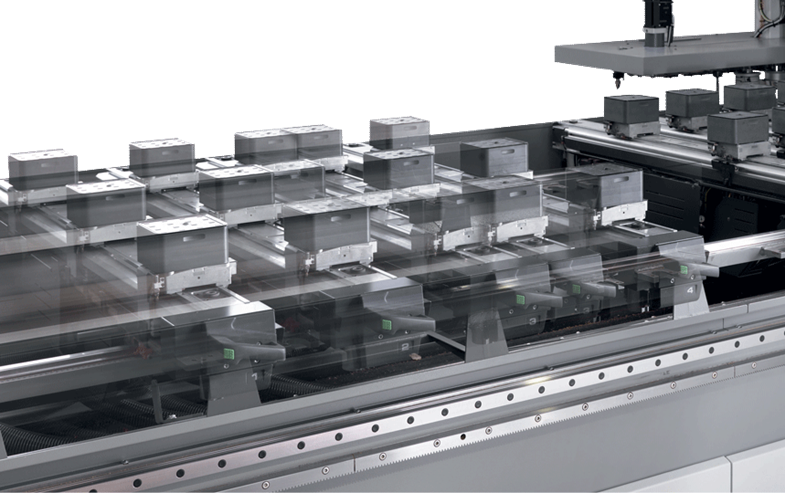

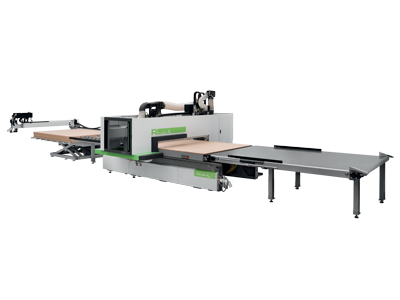

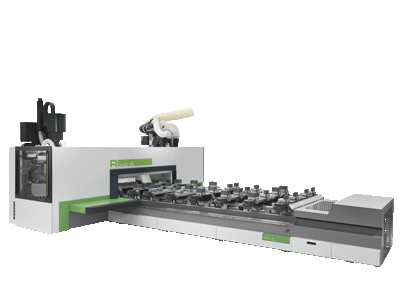

Synchro

Loading and unloading solutions. Automated cell for machining a batch of panels or doors.

Synchro is a loading/unloading device that transforms the Rover CNC machining center into an automatic cell for producing a stack of panels autonomously without the need for an operator:

- it eliminates the risk of damage in the case of heavy panels that need to be handled by 2 operators

- it’s easy to use, because the machining center program also contains the Synchro command instructions

- it has limited overall dimensions, and can be positioned to the left or right of the machining center

- it comes with various configurations, depending on the size of the panels to be handled and the layout of the stacks.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil

.png)

_400x300.png)