Мы упрощаем процесс изготовления изделий, чтобы раскрыть потенциал любого материала.

Наши области применения

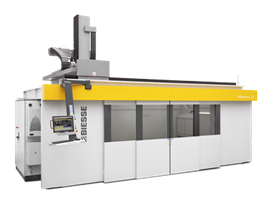

Biesse создает линию станков для термоформовки, обработки пластмасс и композитных материалов: раскройные и обрабатывающие центры, системы гидроабразивной резки, шлифовальные машины и термоформователи.

Выставки и Мероприятия

15

май

25

апр

19

окт

10

окт

Журнал

From 15 to 19 May 2023 LIGNA, the global woodworking technology event, is back and Biesse is present with a new look that expresses the company’s evolutionary journey.

From 25 to 27 April, Biesse will be taking part in Jec World, the annual event dedicated to composite materials and their various applications.

Сегодня последний день выставки Inside, мероприятия, проходящего в Пезаро 10-21 октября, обязательного к посещению, во время которого у клиентов есть возможность вживую познакомиться с технологиями Biesse.

Будьте в курсе

Новые продукты, мероприятия и специальные предложения из мира Biesse!

Digital Arena

сервис видео по запросу, посвященный инновациям Biesse.

Откройте для себя цифровую арену

Зайдите на Digital Arena, платформу бесплатных видео, предлагающую различные вебинары, демопоказы и многое другое по технологиям.

Make

Новый способ узнать Группу Biesse.

Новый способ узнать о компании, движущей силе и инновациях решениях, формирующих репутацию, уважение и статус. Познакомиться с отзывами тех, кто выбрал рост и развитие, и событиями, сопровождающими этот рост. Услышать истории тех, кто каждый день делает это возможным, компетентно и самоотверженно.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil